At dockyards and ports around the world, locals and tourists alike can visit warships whose active duty days have long since passed. After decades of service, these vessels have transitioned from the intense life of active duty to the slow life of a museum attraction. Organizations that take over the responsibility for these vessels need to manage the corrosion and decay of the ships while keeping them true to their best-known design. Let’s take a look at four examples from around the world and learn how different approaches are being used to preserve these historic vessels.

The USS Texas: Floating for over a Century

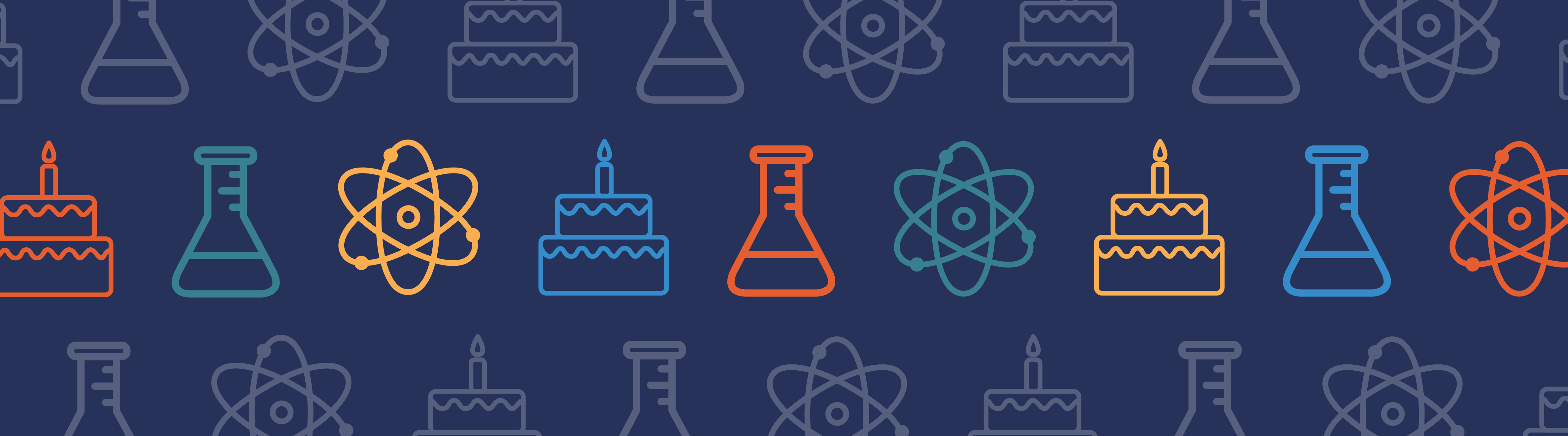

The USS Texas is a New York-class battleship that was commissioned in 1914, served in both world wars, and was converted into a museum and memorial in 1948. The USS Texas remains afloat in retirement, where it continues to weather the forces it was designed to withstand. Being constantly in the water, however, has presented significant challenges for the ship’s managers, the Texas Parks and Wildlife Department (TPWD).

The USS Texas as it appeared in 1919 off New York City. Licensed in the public domain, via Wikimedia Commons.

Corrosion has been the most significant challenge so far. By the 1980s, the ship’s watertight integrity had been so badly compromised that it required a 14-month stay in dry dock for repairs. To fight this corrosion, the ship’s hull and superstructure were sandblasted, and all rusted metal was replaced. Welders and fabricators replaced weakened structural beams and numerous rusted out deck plates in the interior of the vessel as well. In total, more than 350,000 pounds of steel were replaced, and more than 40,000 rivets were seal welded on the underwater hull.

The right side of the USS Texas in dry dock with the torpedo blister removed in 2022. Licensed under CC BY-SA 4.0, via Wikimedia Commons.

To better prevent corrosion issues, the TPWD brought the USS Texas in for another dry-docking period in 2022 and altered the original design of the ship’s leaky torpedo blisters. By squaring off the bottom of these structures, the TPWD believes the ship will be easier to maintain. Regardless of any modifications, however, corrosion will perpetually be an issue as long as the ship remains in water. The tradeoff for this risk is the ease at which the ship can be periodically transported to dry dock for repair. Once there, the operators can inspect the hull, repair any holes, and use epoxy coatings such as PPG Sigma Shield 880 GF to protect against future corrosion.

The Japanese Battleship Mikasa: A Ship on Land

Built around 1900 for the Imperial Japanese Navy, the Mikasa is a pre-dreadnought battleship that served in the Russo-Japanese War, World War I, and the Japanese intervention in Siberia during the Russian Civil War. The Mikasa was decommissioned in 1923 and preserved as a memorial ship with its hull encased in concrete and its engines and guns removed. This decision was the result of a compromise between signatories to the Washington Naval Treaty.

Mikasa as the ship appeared in 1905. Licensed in the public domain, via Wikimedia Commons.

While encasing the Mikasa in concrete has prevented the hull from being in constant contact with the water, corrosion is and will continue to be a problem for the vessel. As seen with steel rebar in concrete, concrete is porous, and corrosive elements, such as water, can seep in. This exposure can have detrimental effects on the long-term health of Mikasa’s steel hull.

Mikasa in Yokosuka, Japan, in 2021, encased in concrete. Licensed under CC BY-SA 4.0, via Wikimedia Commons.

Another challenge associated with the concrete encasement is the lack of structural support. Ships are designed to operate in water with all the associated forces, such as buoyancy and gravity. For example, a ship in water has its entire hull supported under the weight of gravity, while a ship on land (or encased in concrete) lacks axial and lateral support, which can lead to a pancaking effect, flattening the ship over time. Internal supports (which we will examine later on) can be used to help offset this effect.

The HMS Victory: Pilings

One of the more famous museum ships in the world also happens to be the oldest naval vessel still in commission: the HMS Victory. This 104-gun first-rate ship of the line belonging to the Royal Navy was launched in 1765 and commissioned in 1778. After its battle days were over, the ship was moored in Portsmouth, England, where it survived a few near sinkings and a call for its destruction. Fortunately, a naval survey in the 1920s resurrected the ship, and in 1922, it was moved to the No. 2 dock at Portsmouth (the oldest dry dock in the world still in use).

The HMS Victory in dry dock at the Portsmouth Historic Dockyard. Image by Ballista and licensed under CC BY-SA 3.0, via Wikimedia Commons.

Instead of encasing the ship’s hull in concrete or keeping it afloat, the ship’s operators have kept the HMS Victory in dry dock. This approach to preservation eliminates the worries associated with corrosion and rot from sitting in water but has presented its own structural strains. A supporting cradle had to be installed within the dry dock to ease the pancaking effect resulting from the heavy vessel resting solely on its keel. To provide insight into the forces on the wooden hull, the operators of the HMS Victory have added pressure sensors to these supports to ensure the forces are evenly distributed.

The dock walkway that runs underneath the HMS Victory. Seen in the photo are the supports in the dry dock. Image by Type984 and licensed under CC BY-SA 4.0, via Wikimedia Commons.

A painful pair of problems for the operators of the HMS Victory has been rotted wood and pests such as the deathwatch beetle. The conservators are continuously replacing rotting planks and searching for woods and paints that can best endure exposure to the rain, wind, sun, and other environmental factors. According to the ship’s conservation log, areas that have been especially exposed to the elements (such as external planking and gunport lids) have rotted away and been replaced.

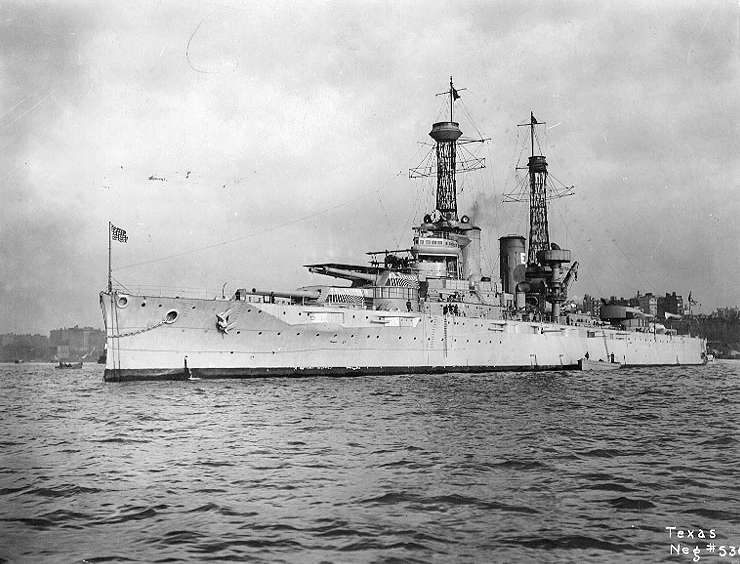

The Vasa: Keeping History Shipshape

The Vasa sank in Stockholm harbor on its maiden voyage in 1628 and remained submerged for over 300 years. This presented a significant preservation problem for those who raised the ship in 1961.

The Vasa from the bow. Image by JavierKohen and licensed under CC BY-SA 3.0, via Wikimedia Commons.

Polyethylene Glycol and Waterlogged Wood

As waterlogged wood dries, it shrinks and cracks. This is particularly true for wood that has been under water for more than three centuries. For this issue, the Vasa Museum’s preservationists turned to synthetic polymer polyethylene glycol (PEG). This synthetic wax diffuses into wood, replacing the water within and preventing the wood from disintegrating. The team began the process by spraying the wood manually but installed an automatic spraying system in 1965. To completely impregnate the wood, the ship was sprayed for 17 years using PEGs with different molecular weights.

The Vasa during the early part of its conservation. Image by Holger Ellgaard and licensed under CC BY-SA 3.0, via Wikimedia Commons.

Controlling the Climate

To further prevent degradation, the Vasa Museum strictly controls the climate and lighting where the ship resides. The humidity within the space is kept at a level that limits biological activity such as mold growth and helps prevent the cracking and shrinking of the wood. The temperature in the museum is kept relatively low to prevent chemical reactions, and similarly, the lighting around the ship is dimmed, as high and intense light levels can break down organic materials. Finally, dust from the visitors can lead to degradation, and so the museum is careful to do daily cleanings of public areas and regular deep cleans of the vessel itself.

Installing a Steel Skeleton

On top of the deployment of PEG and climate control, the Vasa also relies on a structural support system. While this system has done much to mitigate deformation, the museum feels there is room for improvement. They estimate that the ability to carry loads for some sections of the wooden hull has decreased by between 40 and 80 percent. This has prompted an investment in a more substantial system of supports. The newly designed support structure is currently being installed and should be complete in time for the ship’s 400th anniversary in 2028. The 17 external cradle elements are being replaced by 27 steel cradles with a joint under the keel. Further, a steel skeleton is being added to the interior which will run from the keel to the upper deck.

Fighting Time

Whether the museum ship is afloat, encased, in dry dock, or in its own building, any group maintaining these vessels faces an uphill battle against corrosion, rot, and structural strain. While no permanent or agreed-upon long-term solution for all museum ships exists today, it is through experimentation and collaboration that those who operate museum ships can remain afloat.

Further Reading

- Read about ship corrosion and similar content on the COMSOL blog:

Comments (0)