See How Multiphysics Simulation Is Used in Research and Development

Engineers, researchers, and scientists across industries use multiphysics simulation to research and develop innovative product designs and processes. Find inspiration in technical papers and presentations they have presented at the COMSOL Conference. Browse the selection below or use the Quick Search tool to find a specific presentation or filter by application area.

View the COMSOL Conference 2024 Collection

Surface engineering is a key technology used in a wide range of sectors in industry. Among other techniques, it involves adding functionality to a surface. This can be performed by creating a specific topography to a surface using laser texturing. In this paper, the focus is on ... Read More

A 2D transient heat conduction model was created in COMSOL Multiphysics to simulate temperature changes in material irradiated by a KrF laser beam confined on silicon’s surface. In this paper, the obtained results are shown and discussed in case of bulk Silicon. The heat source is ... Read More

The interaction of high power laser beam with metallic materials produces a number of interconnected phenomena that represent a serious challenge for numerical modeling, especially for creation of auto-consistent models. Additional difficulty consists in lack of data on materials ... Read More

Laser beam welding is a key technology in industrial manufacturing as it combines high flexibility and the potential for automation with excellent joint quality and minimal thermal influence of the workpiece. Whereas for materials like steel and aluminium laser beam welding is already ... Read More

The acceleration of protons and ions by highly intense, ultra-short laser pulses is a very active field of experimental and theoretical research. From laser-plasma interactions the emission of a strong electromagnetic pulse (EMP) has often been reported as a side effect. It potentially ... Read More

Hybrid laser-MIG arc welding has very interesting advantages compared to laser welding or arc welding used separately. It is known that improvement of productivity results in higher welding speeds, thicker welded materials, joint fit-up allowance, better stability of molten pool, and ... Read More

Laser material processing at micro-meter domain can be used for a plethora of applications such as micro drilling, micro welding, micro cutting, micro-texturing as well as micro polishing. These processes are governed by the time varying, complex melt hydrodynamics courtesy of melting ... Read More

Attosecond light pulses have revolutionized our view of fundamental atomic, molecular and solid state processes in the attosecond - femtosecond time domain [1]. The availability of such pulses is based on high-order harmonic generation (HHG) in noble gas samples by a femtosecond laser ... Read More

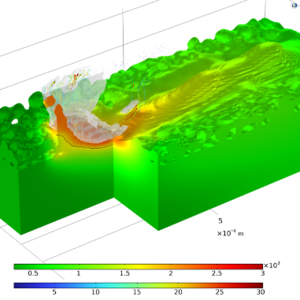

Selective Laser Melting (SLM) offers great potential for future manufacturing technology. In order to extend its applicability for the processing of high melting materials like molybdenum fundamental process understanding is required. This can be obtained by multiphysical simulations ... Read More

Simulation of laser processes are more and more efficient. In some cases, as welding and additive manufacturing, the physical phenomena are complex, multi-physics and multi-phases, thus some assumptions have to be done. For Laser Powder Bed Fusion, a laser beam melts and vaporizes the ... Read More