See How Multiphysics Simulation Is Used in Research and Development

Engineers, researchers, and scientists across industries use multiphysics simulation to research and develop innovative product designs and processes. Find inspiration in technical papers and presentations they have presented at the COMSOL Conference. Browse the selection below or use the Quick Search tool to find a specific presentation or filter by application area.

View the COMSOL Conference 2024 Collection

Hybrid laser-MIG arc welding has very interesting advantages compared to laser welding or arc welding used separately. It is known that improvement of productivity results in higher welding speeds, thicker welded materials, joint fit-up allowance, better stability of molten pool, and ... Read More

A Laser-welded blank (LWB) consists of steels of different thicknesses and/or grades welded together to produce a single blank prior to the forming process. LWB are mostly used in the automotive field where the high productivity of the laser welding process is an advantage. Numerical ... Read More

Additive Layer Manufacturing (ALM) methods, like Electron Beam Sintering (EBS), constitute an interesting process concerning the production of small series and customized products. However, transient effects occur during processing due to the different physical principles of an electron ... Read More

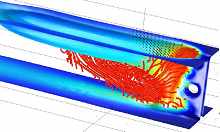

The application of an oscillating magnetic field on the high-power full-penetration laser beam welding process of a 20 mm thick stainless steel plate was numerically and experimentally investigated. In the simulations, three-dimensional heat transfer and fluid dynamics as well as ... Read More

The interaction of high power laser beam with metallic materials produces a number of interconnected phenomena that represent a serious challenge for numerical modeling, especially for creation of auto-consistent models. Additional difficulty consists in lack of data on materials ... Read More

A 2D transient heat conduction model was created in COMSOL Multiphysics to simulate temperature changes in material irradiated by a KrF laser beam confined on silicon’s surface. In this paper, the obtained results are shown and discussed in case of bulk Silicon. The heat source is ... Read More

For a better understanding of phenomena associated to the appearance of defects in laser welding, a heat and fluid flow model is developed. This study is focused on the modeling of a static laser shot on a sample of steel. This 2D axialsymmetric configuration is used to study phenomena ... Read More

The initiation in numerical modeling of welding with COMSOL Multiphysics® is proposed to the 2nd year students of the professional master program «Processes, Controls, Metallic Materials: Nuclear Industry» (PC2M) of University of Burgundy, France since 2016 within the module «Simulation ... Read More

Arc current welding is a widespread process in heavy industry for the assembly of metallic components. In order to ensure the good quality of assemblies welds, it is appropriate to master the welding process but also to have a deep understanding of interactions with the weld pool and ... Read More

Laser direct deposition is a process, different from molding or machining, which allows the producing of fully densified and operational components. This technique involves injecting metal powder through a coaxial nozzle into a melt pool obtained by a moving laser beam. The final object ... Read More