support@comsol.com

Polymer Flow Module Updates

For users of the Polymer Flow Module, COMSOL Multiphysics® version 6.1 introduces materials for multiphase flow couplings, inelastic non-Newtonian material property groups, and nonisothermal viscoelastic flow simulations. Read more about these updates below.

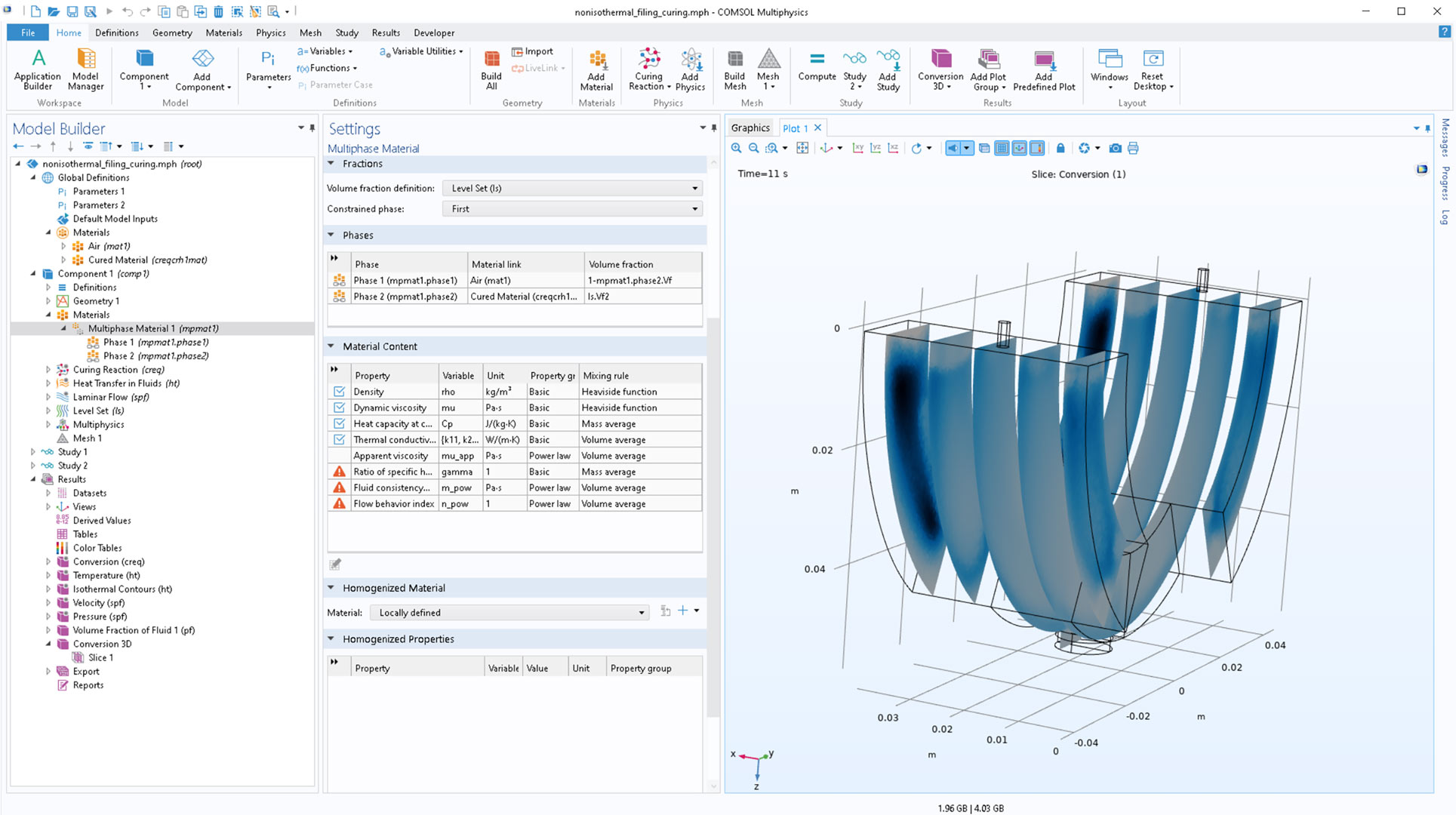

Multiphase Materials for Multiphase Flow Couplings

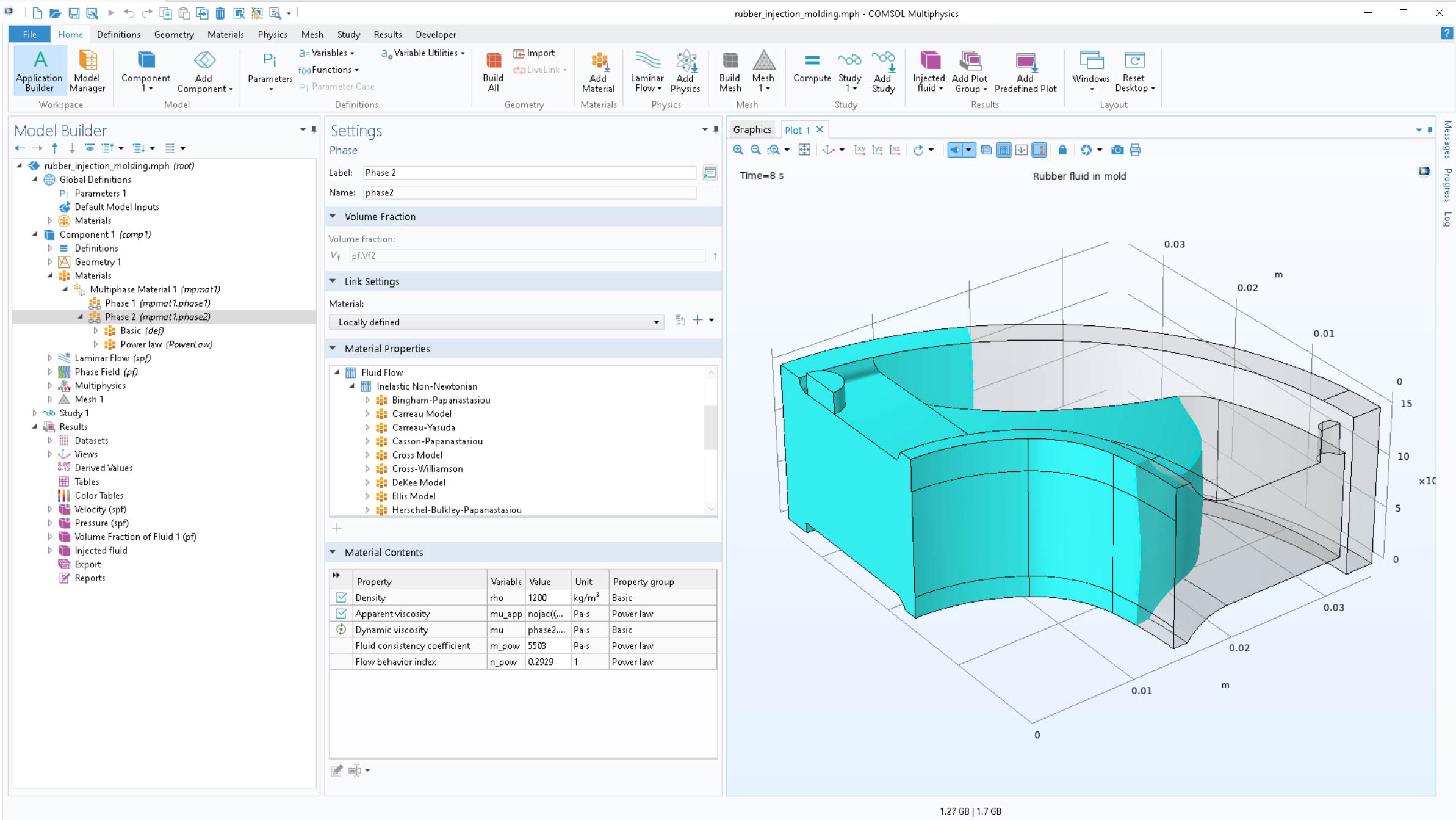

The Two-Phase Flow, Level Set, Two-Phase Flow, Phase Field, and Three-Phase Flow, Phase Field multiphysics couplings have a new option to obtain the effective material properties from a Multiphase Material node, with built-in mixing rules. This is especially efficient when coupling these multiphysics interfaces with other physics, such as heat transfer or electrostatics, since the multiphase material will use appropriate mixing rules for nonfluid material properties. In previous versions, this would require you to write user-defined expressions based on the volume fraction of each fluid phase to compute the effective material properties used in each physics interface. The existing 2D Non-Newtonian Slot Die Coating and Rubber Injection Molding models showcase this new feature.

A simulation of rubber injection into a mold. The two-phase nonisothermal flow is coupled with cure kinetics.

Inelastic Non-Newtonian Material Property Groups

Dedicated material property groups have been added for most of the inelastic non-Newtonian models available in Polymer Flow Module. Each material property group contains all necessary material parameters and the apparent viscosity expression. It picks up the shear rate from a Fluid Flow interface to define the dynamic viscosity for fluid by means of a synchronization rule. Thus, an inelastic non-Newtonian model can be selected directly by adding the corresponding Material Properties group as a subnode to a material node. You can see this new feature in the following models:

Setting up a material by adding a Power Law material property group for the Behavior of a Power-Law Fluid in a Mixer model.

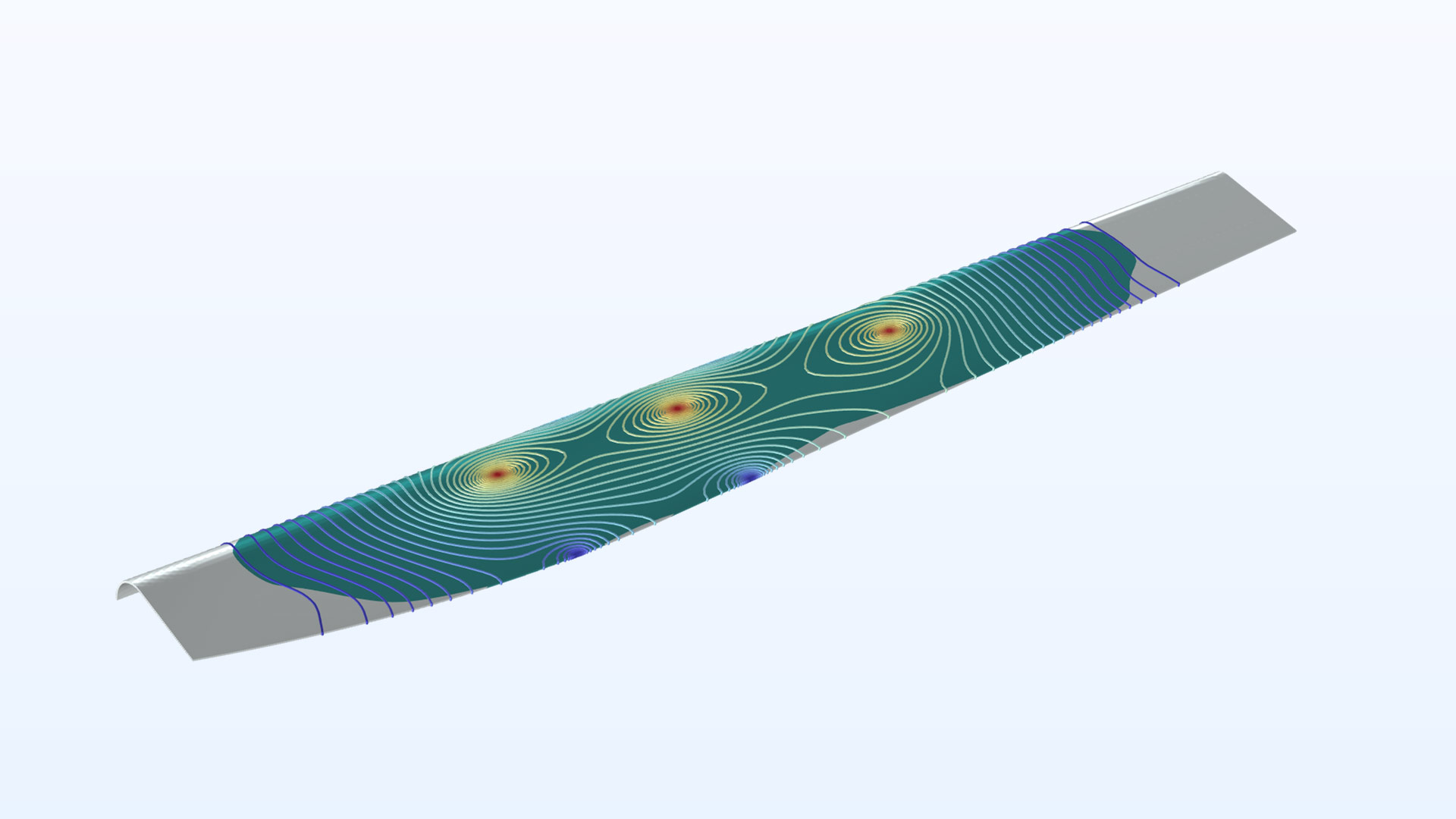

Nonisothermal Viscoelastic Flow

The Fluid Properties node in the Viscoelastic Flow interface now includes the option to specify the temperature dependence of the material properties using a set of predefined thermal functions.

The new Nonisothermal Flow multiphysics coupling can be used to couple the Viscoelastic Flow and Heat Transfer in Fluids interfaces. The heat source, corresponding to heating due to irreversible losses, is accounted for if the Include irreversible losses check box is selected. The new Nonisothermal Flow, Viscoelastic Flow interface includes the Viscoelastic Flow and Heat Transfer in Fluids interfaces and the Nonisothermal Flow multiphysics coupling.

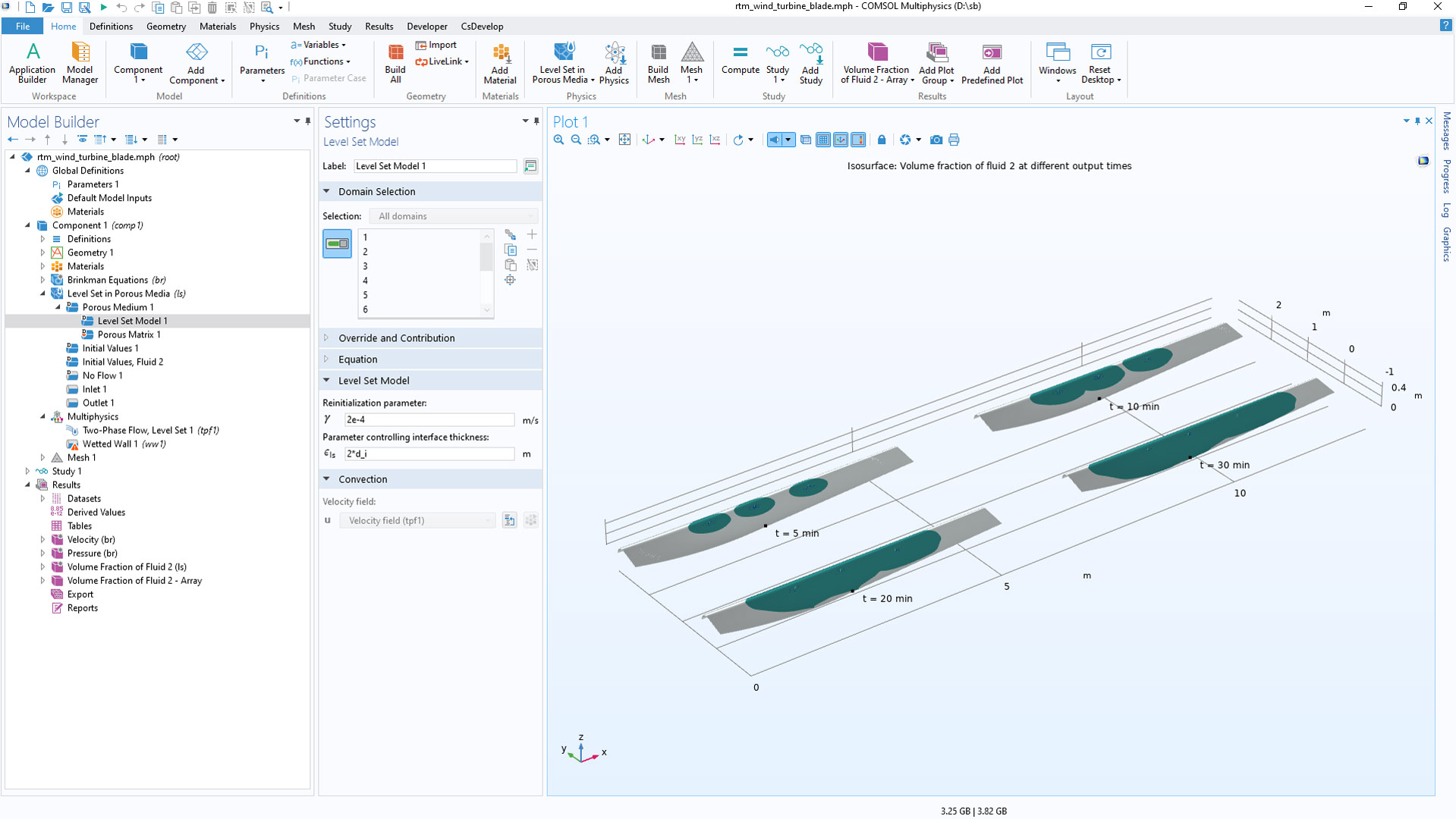

Improvements to the Level Set Interface

In the Level Set interface, a new Porous Medium feature can link to the definition of the porosity given in the Porous Material node. The Brinkman Equations, Two-Phase Flow, Level Set multiphysics interface and the new Level Set in Porous Media interface include this new feature by default. View this improvement in the new Resin Transfer Molding of a Wind Turbine Blade model.

New Tutorial Model

COMSOL Multiphysics® version 6.1 brings one new tutorial model to the Polymer Flow Module.