Fluid & Heat Blog Posts

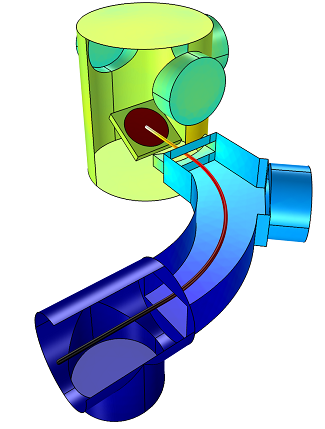

Coupling Transport and Solid Mechanics Models for Better Puffed Rice

In my work at COMSOL, it’s always interesting to see how broad the field of heat transfer can be. Far from being limited to steel ingots and CPU fans, researchers often use COMSOL Multiphysics to study heat transfer in food manufacturing. One good example of this is the study of thermal and mechanical effects in the production of puffed rice, which was presented at the COMSOL Conference 2013 in Boston.

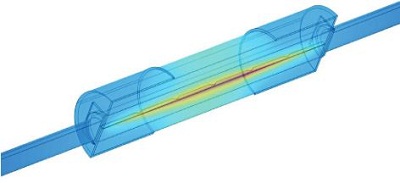

Mersen Simulates Joule Heating in Busbars and Fuses

Joule heating is a fairly standard type of simulation for COMSOL users nowadays. It involves solving for electrical voltage and temperature fields simultaneously with highly temperature-dependent material properties. Controlling Joule heating is very important when designing and manufacturing electrical systems components. The electric protection group at manufacturing company Mersen France used to base their busbar and fuse designs on trial-and-error, but these days they turn to COMSOL Multiphysics.

Thermometer Calibration: When Experimentation Falls Short

The International Temperature Scale of 1990 (ITS-90) is the industry calibration standard for measuring temperatures throughout the world. The National Physical Laboratory (NPL) works to establish and maintain the ITS-90 through experiments, most notably, thermometer calibration. To better understand and overcome the shortcomings of the experimental process, Jonathan Pearce, at the UK’s National Physics Laboratory, turned to simulation. His results yielded fascinating results about the microscopic behavior of the liquid-solid interface during the freezing process.

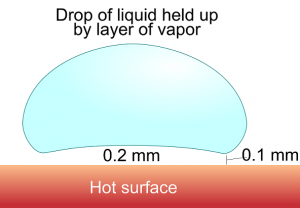

Exploring the Leidenfrost Effect

The Leidenfrost effect, also known as film boiling, occurs when a liquid comes into contact with a solid that is at a temperature well above the liquid’s boiling point. Upon contact, a layer of vapor forms between the liquid-solid interface, creating a barrier between the two. There are many examples of this phenomenon, ranging from something you may have seen in your kitchen (water “dancing” around in a pan) to things you shouldn’t try at home (dipping your hand into […]

Learn about Modeling Vacuum Systems in COMSOL

Until recently, simulation had not been widely used by vacuum system designers because of an absence of commercial simulation tools. Last October, my colleague James Ransley held a webinar about how to model vacuum systems using COMSOL Multiphysics. The webinar was a great success, and it inspired us to produce a dedicated product for modeling vacuum applications: the Molecular Flow Module (new with version 4.3b). This year, on November 21st, James will be giving a webinar explaining the new features […]

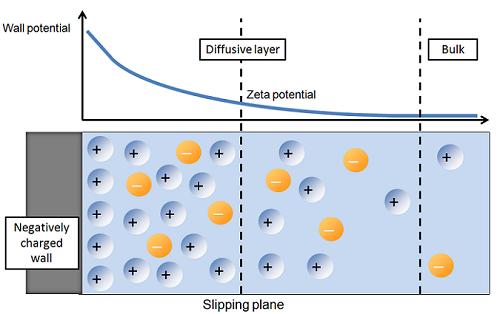

Modeling Electroosmotic Flow and the Electrical Double Layer

Microfluidic devices are so small that the micropumps and micromixers that control and mix the fluid inside the device cannot involve any moving components. Instead, they must take advantage of electroosmotic flow. Here, I will describe the concept of electroosmosis and the electrical double layer (EDL), and how to model these in COMSOL, walking you through two example models.

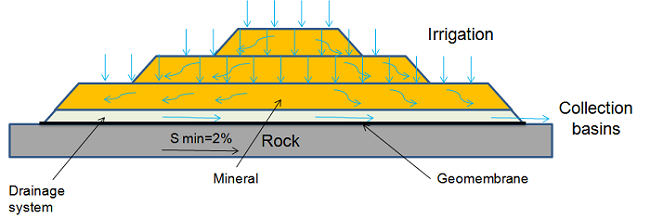

Porous Media Flow Simulations for the Mining Industry with AMPHOS 21

The mining industry pre-dates sophisticated simulation software and the computers it runs on by thousands of years. As an essential modern industry, however, the technical and analytical capabilities offered by AMPHOS 21, a COMSOL Certified Consultant, are critical for both understanding and optimizing mine operations. Recently, we sponsored a webinar together with NASA Tech Briefs on “Mining and Hydrogeology: Porous Media Flow Simulations with COMSOL”, featuring environmental consultants Jorge Molinero and Elena Abarca from AMPHOS 21. Here are some of […]

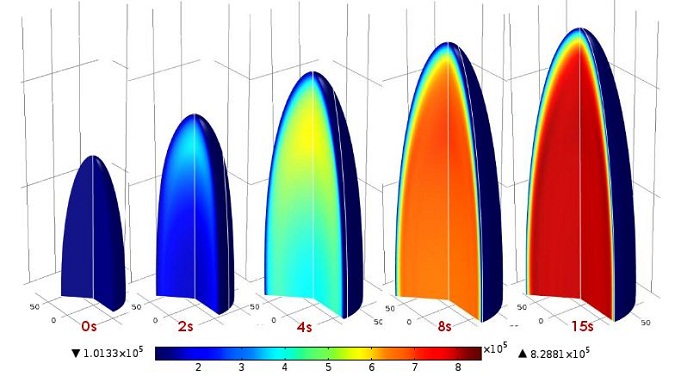

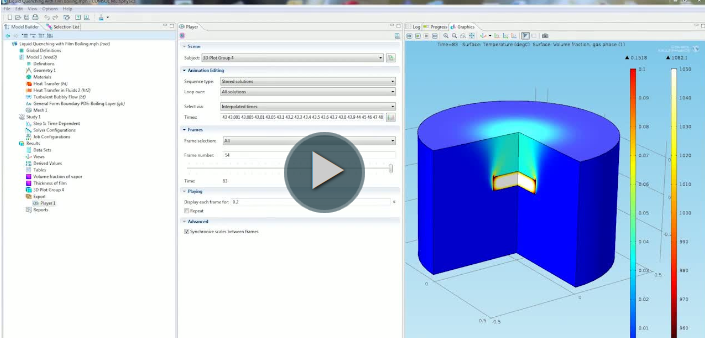

Liquid Quenching with Film Boiling Simulation by AltaSim

The process of quenching a red-hot metal object in a cool liquid bath is simple in practice, but highly complicated when creating a simulation. There are several phases of liquid quenching, and here we will focus on the initial phase: film boiling. In the accompanying video, COMSOL Certified Consultant AltaSim Technologies details the steps taken to model a nickel superalloy puck that is quenched in a tub of oil.