Microfluidic systems manipulate fluids through microchannels that are often smaller than a human hair. Micropumps are key components of these systems, with applications ranging from biological fluid handling to microelectronic cooling. Multiphysics simulation enables engineers to design micropumps with the precision required to build on such a small scale.

Editor’s note: The original version of this post was published on July 17, 2015. It has since been updated to include new text and new versions of the model images.

Micropump Design Challenges

Manipulating fluids by mixing, separating, and pumping them throughout microchannels poses certain design challenges. Engineers must create micropumps that meet miniature size requirements and still have optimal performance. Valveless pumps are often chosen for micropump applications because of their simple design as well as for being gentler on biological material. However, it’s challenging to control sustained, unidirectional fluid flow without the check valves of a traditional pump. Valveless micropumps instead rely on the interaction between the mechanism’s geometry and the fluid to achieve unidirectional flow. Because of this, valveless pump designs are ineffective for fluid with a low Reynolds number, or if the application involves viscous fluids, small length scales, or low flow rates. Veryst Engineering, a COMSOL Certified Consultant, developed a model of a valveless micropump mechanism that overcomes this design limitation.

In Veryst’s model, the micropump creates oscillatory fluid motion induced by, for example, a reciprocating pumping mechanism. The fluid enters a horizontal channel with bendable microflaps positioned at a slanted angle on either side of the micropump. The microflaps bend in response to the motion of the fluid, which results in unidirectional flow without having to use the complicated synchronized actuation mechanisms that would be required in a valve-based system.

The geometry of the micropump mechanism tutorial.

The geometry of the micropump mechanism tutorial.

Evaluating the Micropump’s Performance with Simulation

In this model, the Reynolds number is set to 16 but is also valid for Reynolds numbers significantly less than 1. The Fluid–Structure Interaction interface in the COMSOL Multiphysics® software is used to set the input oscillatory flow as well as the properties of the microflaps and then calculate the response of the flaps and the effect on the fluid flow. The Global ODEs and DAEs interface calculates the net volume pumped as a function of time throughout a two-second pumping cycle.

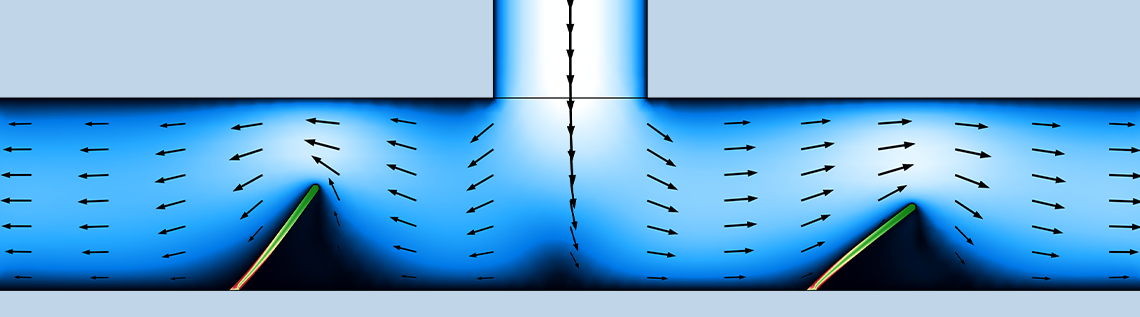

The simulation starts with the micropump’s downstroke, which is when the micropump pushes fluid down into the vertical chamber. This action causes the microflap on the right to bend down and the microflap on the left to curve up. In this position, the left microflap is obstructing the flow to the left, and the flow channel on the right is widened. This setup naturally causes a majority of the fluid to flow to the right because it is the path of least resistance.

The velocity magnitude, velocity field, and von Mises stress are measured during the pumping downstroke, where the majority of fluid is pushed to the right.

The velocity magnitude, velocity field, and von Mises stress are measured during the pumping downstroke, where the majority of fluid is pushed to the right.

During the pumping upstroke, fluid is pumped up into the vertical chamber. This flow from the upstroke causes the microflaps to bend in the opposite directions than they did in the downstroke. This shift doesn’t change the direction of the net flow, because now the majority of the fluid is drawn into the flow channel from the inlet on the left.

At a time of 0.76 seconds, the fluid is pulled up, and most of it flows from the inlet on the left during the pumping upstroke.

At a time of 0.76 seconds, the fluid is pulled up, and most of it flows from the inlet on the left during the pumping upstroke.

Due to the natural deformation of the microflaps caused by the moving fluid, both of these stages created a left-to-right net flow rate. But how well did the micropump mechanism do at maintaining this flow over the entire simulation time period?

The net fluid volume that is pumped from left to right as a function of time.

The net fluid volume that is pumped from left to right as a function of time.

During the two-second test, the net volume pumped from left to right was continually increased, with a higher net flow rate during peaks of the stroke speed. This demonstrates that the valveless micropump mechanism model can perform effectively at such a low Reynolds number, overcoming a limit common in many valveless micropumps.

This valveless micropump mechanism could have many future applications, one of which is to work as a fluid delivery system. In such a scenario, a micropump mechanism could take fluid from a droplet reservoir on its left and move it through a microfluidic channel to an outlet on its right.

Next Step

In this blog post, we have shown just one set of simulation results. By experimenting with the tutorial model set up by Veryst Engineering, you can visualize how a valveless micropump may work in different scenarios.

Comments (0)