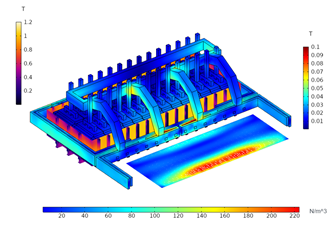

Magnetic field and magnetohydrodynamic behavior of a typical aluminum cell modeling with COMSOL Multiphysics®

Aluminum production potlines operate under significant amperage in a range of 200 kA – 600 kA. High electrical DC currents induce strong magnetic fields. MHD stability, which is a result of electrical current and magnetic field interaction within aluminum reduction cell, is one of highly important factors, which has to be considered in the design. Previous works on modelling magnetic field within aluminum production cell were based on scalar magnetic potential codes including Biot-Savart integration. Only recent studies included COMSOL Multiphysics® simulations of magnetic field inside aluminum electrolysis cell using vector magnetic potential. This article presents numerical modeling of the electromagnetic fields and their effect on molten electrolyte and aluminum flow within the cell using COMSOL Multiphysics® software. Two uncoupled models were developed for evaluation of the magnetic field and prediction of magnetohydrodynamic behavior of the operating fluids.