Modeling of the Magnetic Field in a Vacuum Arc Remelting Furnace using COMSOL Multiphysics®

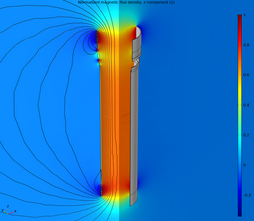

The vacuum arc remelting is a refining process used to melt reactive metals like titanium, zirconium or hafnium. Melting is performed under vacuum to avoid reactions between liquid metal and oxygen which could be a source of pollution. This process is particularly well suited to purify impurities at high temperature and to minimize the segregation. Therefore, the company Framatome used it to produce Zirconium alloys dedicated to nuclear fields and medical fields. The VAR process consists in applying a current intensity between a zirconium electrode and the mold intended to receive the melted metal. An electric arc occurring between these two electrodes enables the bottom of the zirconium electrode to melt and fill in the mold. The cooled mold is usually made of copper and equipped with coils to apply an electromagnetic stirring. The control of the process is essential to ensure quality through chemical composition and structural homogeneity. For this reason, Framatome and Simtec companies have developed the modeling of the magnetic field in a vacuum arc remelting furnace using COMSOL Multiphysics®. This model is especially used to check the capacity of the system to ensure a homogeneous magnetic field for different melt parameters of different products. The evolution of the calculated magnetic field is discussed for different current intensities and compared with experimental values. The good agreement between the calculated and experimental results allows to improve both the coils design and the control of the process.

Download

- C2020-10-02-Comsol-P01-article6.pdf - 0.48MB