Thermal study of wafer cooling and heat resistance fitting

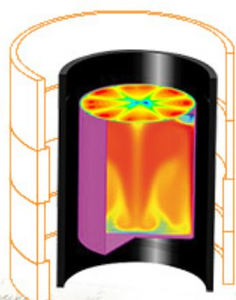

Temperature management and homogeneity on wafers has always an important effect on production in all microelectronics fields. The heat resistance of every mechanical contact, not only clamping, may decrease the precision of temperature regulation. But they also increase the difficulties to manage the thermal homogeneity of the wafer: the heater or cooler effects are not direct on the wafer. This problem is higher at lower temperature, when radiative transfer is low through mechanical tolerances. In an other hand modeling heat transfer with such mechanical tolerances is also inaccurate. But the modeling precision may be increased by fitting some equivalent heat resistance from modeling to measurements correlation. In the presented case we help an equipment provider to check and improve temperature homogeneity of a single wafer reactor. An equivalent resistance was affected to each kind of mechanical tolerance. The a simple numerical DOE (Design of Experiment) was perform to fit these parameter. The comparison was done on the deposition rate which is directly related to wafer temperature in that process case. Finally the model give the wafer temperature with a quite good precision (Drawing 1) and has been used for design optimization. This study was done using the Heat Transfer model. In that case the liquid cooling flow was not modeled in detail because we assume a “piston” flow with homogeneous cooling. This allow faster modeling.

Download

- Europe_2020_Poster_INOPRO_IAO.pptx - 0.55MB