See How Multiphysics Simulation Is Used in Research and Development

Engineers, researchers, and scientists across industries use multiphysics simulation to research and develop innovative product designs and processes. Find inspiration in technical papers and presentations they have presented at the COMSOL Conference. Browse the selection below or use the Quick Search tool to find a specific presentation or filter by application area.

View the COMSOL Conference 2024 Collection

Laser percussion drilling is widely used in the aerospace industry to produce cooling holes in jet engine components. This process is a thermal, contact-free process which involves firing a sequence of focused optical pulses onto a target material [1-4]. During each optical pulse, the ... Read More

Simulation of laser processes are more and more efficient. In some cases, as welding and additive manufacturing, the physical phenomena are complex, multi-physics and multi-phases, thus some assumptions have to be done. For Laser Powder Bed Fusion, a laser beam melts and vaporizes the ... Read More

A numerical model of laser welding process applied on highly optically reflective and thermally conductive materials such as copper has been developped. The latter considers multiphysical couplings of CFD, heat transfers and phase-field representation to account for topological ... Read More

In this paper, we present a study of the simulation of Directed Energy Deposition (DED) Additive Manufacturing (AM) using a multiphysics approach. We use a combination of Heat Transfer in Fluids, Solid Mechanics and Laminar Flow physics to accurately simulate the DED process. The ... Read More

The present work introduces a new methodology, based on COMSOL Multiphysics® Application Builder, to account for the “beam trapping” effect in multiphysical modelling of laser welding. Incident intensities involved in laser welding processes are high enough to induce material ... Read More

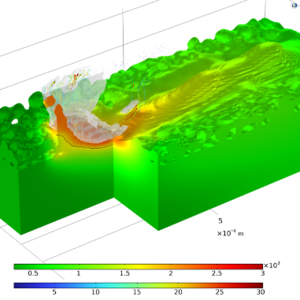

An auto-consistent multiphysical 3D model with strong coupling between Heat Transfer, Navier Stokes and ALE problems is proposed for the description of transient development of the keyhole and the melted zone in laser welding of metallic materials. It showed a satisfactory correspondence ... Read More

Laser cladding is an additive manufacturing process, where a laser beam creates a melt pool, into which powder is fed from a powder nozzle. Due to the feed motion of the laser beam and the powder nozzle relative to the workpiece, coatings and 3D parts can be deposited, which consist of ... Read More

Selective Laser Melting (SLM), like many other additive manufacturing techniques, offers flexibility in design expected to become a disruption to the manufacturing industry. The current cost of SLM process does not favor a try-and-error way of research; which gives more room for ... Read More

Laser metal deposition is widely adopted for coating, reparation and 3D printing. Using COMSOL, we have developed a numerical model with full coupling of laminar fluid flow and heat transfer. The Marangoni effect is considered to capture the enhanced convective heat transfer as well as ... Read More

The heat and fluid flow calculation inside the melt pool in welding processes is a complex challenge. It can be useful to predict defects in the weld seam or to study the influence of some process parameters. Even if the required equations are mastered over the last few years, the cost ... Read More