See How Multiphysics Simulation Is Used in Research and Development

Engineers, researchers, and scientists across industries use multiphysics simulation to research and develop innovative product designs and processes. Find inspiration in technical papers and presentations they have presented at the COMSOL Conference. Browse the selection below or use the Quick Search tool to find a specific presentation or filter by application area.

View the COMSOL Conference 2024 Collection

Distributed Feedback Fiber Laser (DFB-FL) sensors are increasingly used in aeronautical applications. One of the newest such applications consists in detecting the “transition” zone between laminar and turbulent air flow upon the extrados surface of an aircraft wing. In this specific ... Read More

This study investigates the feedback between fault slip and dike intrusions during the Mono-Inyo eruption sequence of ~1350 A.D. (Mono Basin, California). We perform an extensive validation of 3D finite element models, implemented in the Structural Mechanics module of COMSOL ... Read More

In COMSOL Multiphysics it is possible to implement and simulate several independent models in parallel. This can be meaningful when the different models are coupled to each other by some kind of interaction. If a part of the geometries is identical in all models, this part can be reduced ... Read More

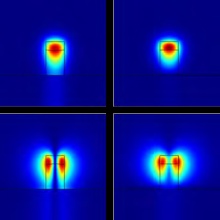

The finite-element method (FEM) (COMSOL RF Module) has been employed for modal analyses of porous silicon (PSi) waveguides composed of a guiding layer of low porosity (high refractive index) on a cladding layer with higher porosity (lower refractive index). These can be made by switching ... Read More

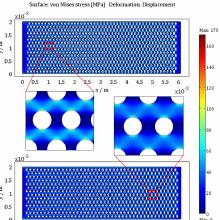

Porous membranes with pore sizes in the micrometer scale are required in many micro systems dedicated to biological and chemical applications. If their thickness is in the same dimension like the pore diameter they are called microsieves. On the one hand, a thin membrane guarantees a ... Read More

The fabrication of piezo aluminium composite modules for sensor and actor applications with mass production technologies is in the scope of the SFB/Transregio 39 PT-PIESA project funded by the (German Research Foundation). After forming of cavities with a width of 0.3 mm into aluminium ... Read More

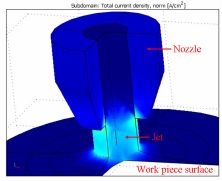

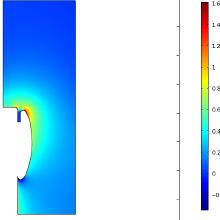

Electrochemical Machining is a potential procedure for micro manufacturing technology. Especially the absence of machining forces makes it advantageous for processing metals with high hardness and for the generation of complicated geometries. Applying a closed electrolytic free jet (Jet ... Read More

Simulation tools for building physics problems play an important role in design and understanding the behavior of energy efficient buildings. There are different tools available for simulation of these problems, but each simulation tool has its own advantages and limitations. In this ... Read More

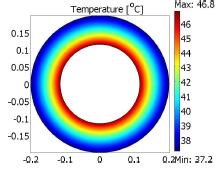

The axial injection torch (AIT) produces high-density plasmas by coupling microwave power to a flowing gas. The plasma is imposed by defining its electron density and temperature whose maximum are given by optical emission spectroscopy diagnostics. Our study of an AIT with COMSOL ... Read More

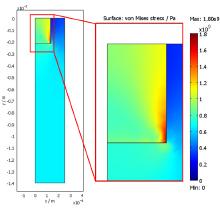

Controlling electric field distribution in high voltage components is critical to avoid excessive electric stress on the insulation and thus reducing the risk of insulation breakdown and damage to equipment. For subsea applications this is even more important due to the costs involved in ... Read More