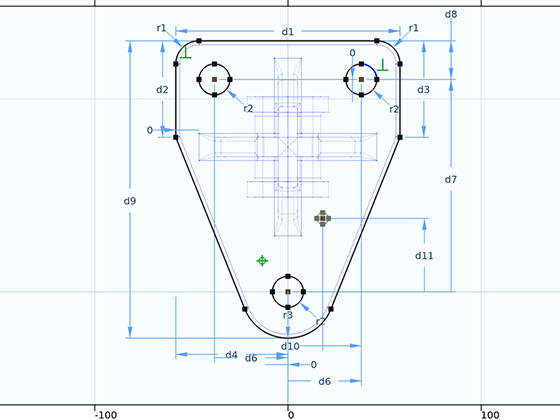

Constraints and Dimensions

The Design Module includes a set of sketching tools used for adding constraints and dimensions to planar drawings for 2D models, 3D work planes, and in geometry parts. Some of the available constraint options include parallel, perpendicular, and tangent constraints. For example, to make two polygon segments meet at 90 degrees, the two edges are clicked and perpendicular constraint is used. The options for dimensions include, among others, length dimension, radius, and angle. Interactively setting a length dimension, for example, is as simple as clicking and dragging an edge. To aid in creating consistent drawings, the Design Module provides immediate feedback, whether a sketch is underdefined, overdefined, or well defined.

All of the dimensions detailed above can be made parametric using the general parametric framework in COMSOL Multiphysics®. This makes it possible to run parametric sweeps across one or multiple dimensions. Additionally, when combined with the Optimization Module, parametric optimizations can be performed.