Optimizing Elastomeric Mechanical Cell Stretching Device

Cell morphology, orientation, and fate of differentiated stem cells can be affected by mechanical stimulation. Mechanobiological studies help to understand the molecular mechanisms of cells sensing and responding to mechanical cues. Previously, we have developed a vacuum-operated stretching device to study differentiation of human induced pluripotent stem cells into cardiomyocytes under equiaxial strain. The stretching was based on the deformation of a planar membrane in the device made of polydimethylsiloxane (PDMS) elastomer. [1] However, relatively large out-of-plane (vertical) movement of the membrane disturbed the high-magnification imaging of the cells during the stretching. To overcome this issue, we used the Optimization Module from COMSOL Multiphysics® to minimize the undesired vertical movement while remaining the strain approximately at a same level.

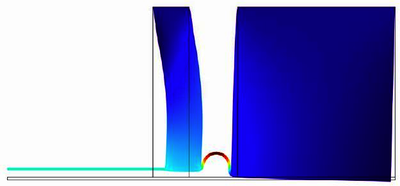

The developed COMSOL Multiphysics® 2D Axisymmetric model used the Solid Mechanics interface including the Contact Pair and Contact nodes to model contacts between the membrane and the device under different negative pressures between 0 and 400 mbar. Furthermore, we included two Point ODEs and DAEs interfaces in the model to track the minimum and maximum vertical movement of the center point of the membrane (where the cells are located). As material of the device, PDMS, is a silicone-based organic polymer, the Hyperelastic Material node was added and PDMS was modeled using the Neo-Hookean hyperelastic material model for nearly incompressible material. Used material parameters were the following: density (971 kg/m3), Young’s modulus (2 MPa), Lamé parameter (667 kN/m2), and bulk modulus (333.3 MPa). [1]

In the optimization study, we first defined two constrains within the given pressure range (0 to 400 mbar): the strain of the membrane should be at least 10%, and the vertical movement of the membrane should not exceed 50 µm to guarantee that high-magnification imaging can be performed. In the study, the goal was to minimize the objective function that included the normalized maximum vertical movement and the normalized required vacuum pressure. Several geometrical parameters were used as control variables, and Monte Carlo method was used as an optimization solver. This solver was used because of our preliminary studies showed that results with different geometries were very non-linear and quite random, thus other solvers would find only local minima, not a global solution. The optimization study provided a geometry that resulted over 10% strain and below 50 µm the vertical movement of the membrane with a required pressure smaller than 400 mbar. To verify the presented model, experiments with the proposed geometry are planned to be performed in the future.

[1] J. Kreutzer, L. Ikonen, J. Hirvonen, M. Pekkanen-Mattila, K. Aalto-Setälä, and P. Kallio, “Pneumatic cell stretching system for cardiac differentiation and culture,” Med. Eng. Phys., vol. 36, no. 4, pp. 496–501, 2014

Download

- mäki_presentation.pdf - 3.52MB

- mäki_abstract.pdf - 0.13MB