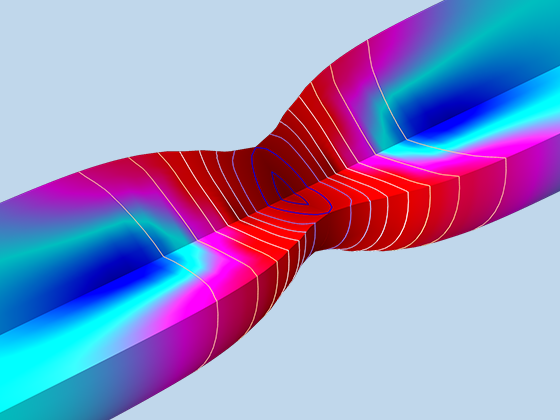

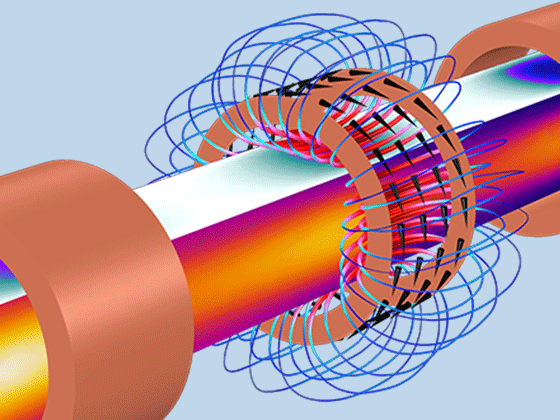

Steel Quenching

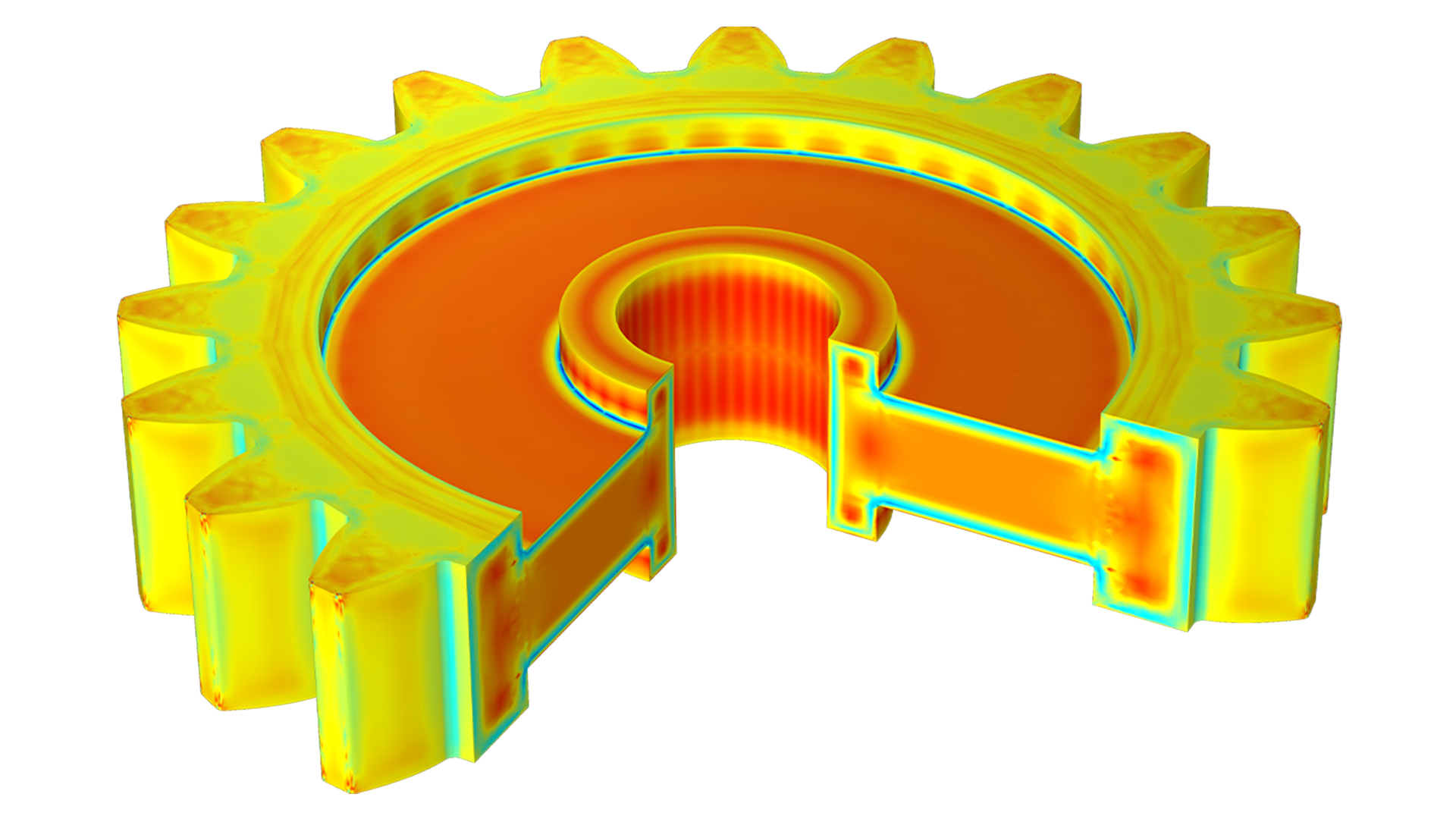

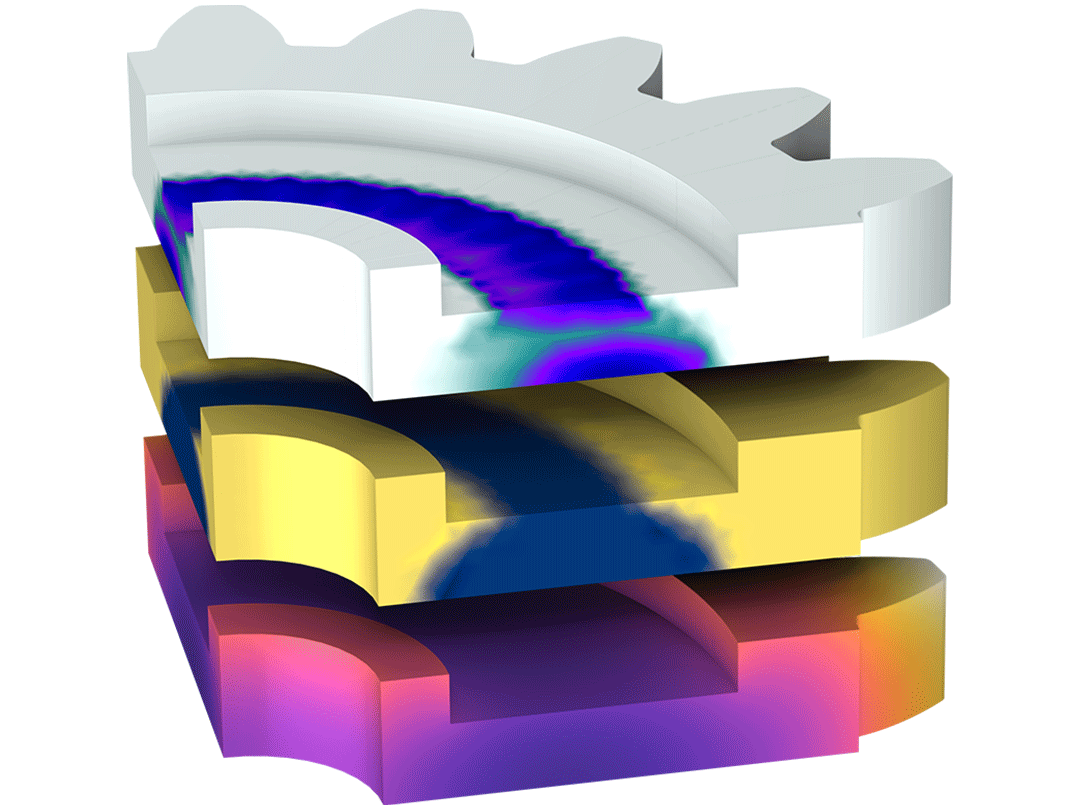

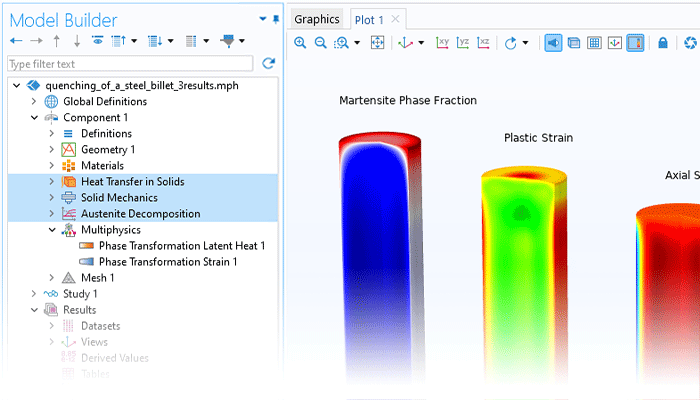

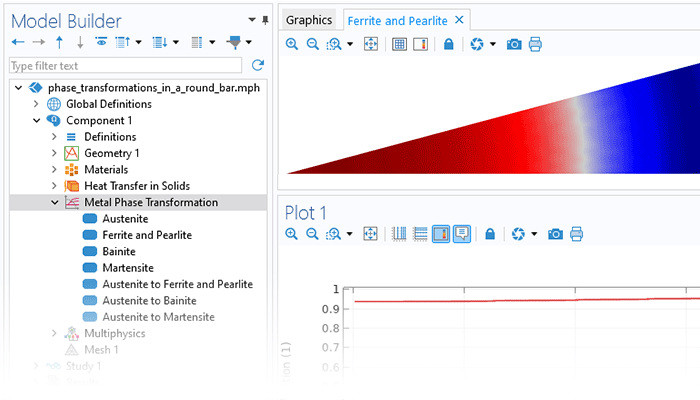

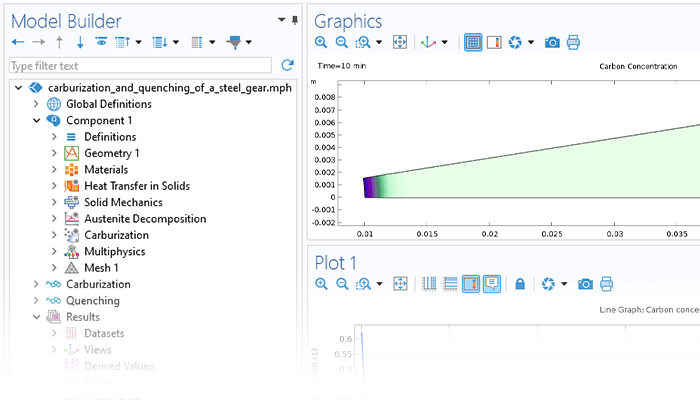

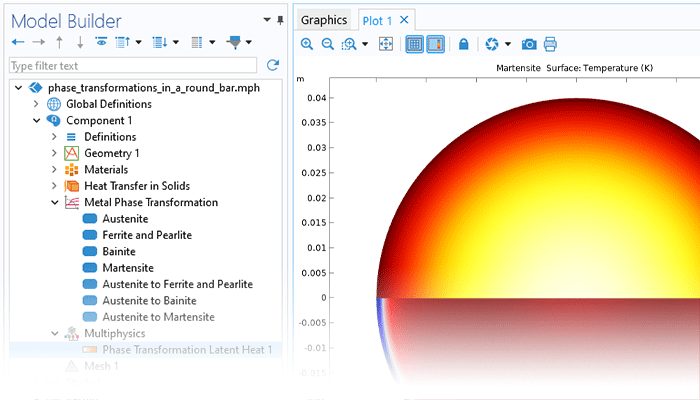

Steel quenching is a heat treatment process where steel parts that have been heated to a fully austenitic state are rapidly cooled. Steel quenching is also a multiphysics process, as it involves a combination of austenite decomposition, heat transfer, and structural analysis. The Metal Processing Module provides specialized features and functionality to facilitate the model setup for this multiphysics process.

After running the analysis, phase compositions and the influence of cooling rate on the final distortions and residual stresses during the quenching of a component can be examined. These results provide insight into the efficacy of a certain quenchant and how the physical geometry of a component affects the attainable phase composition in its interior.