Efficient Pipe Flow Modeling

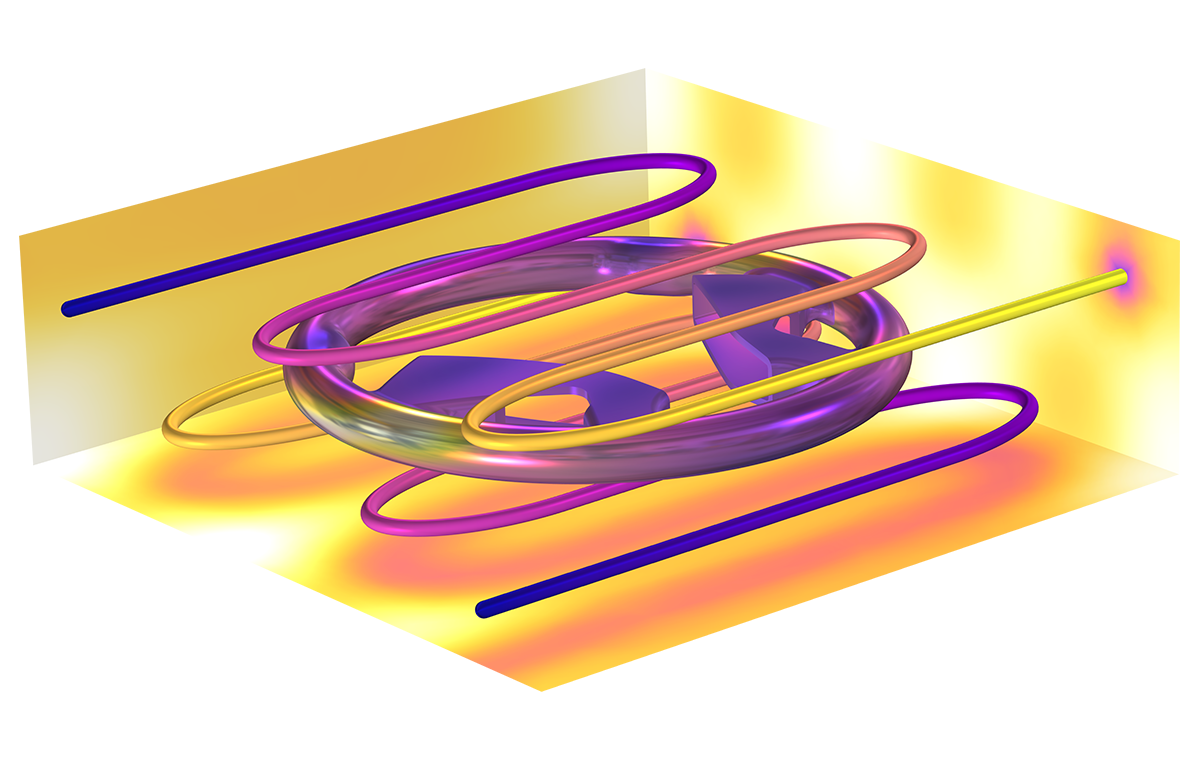

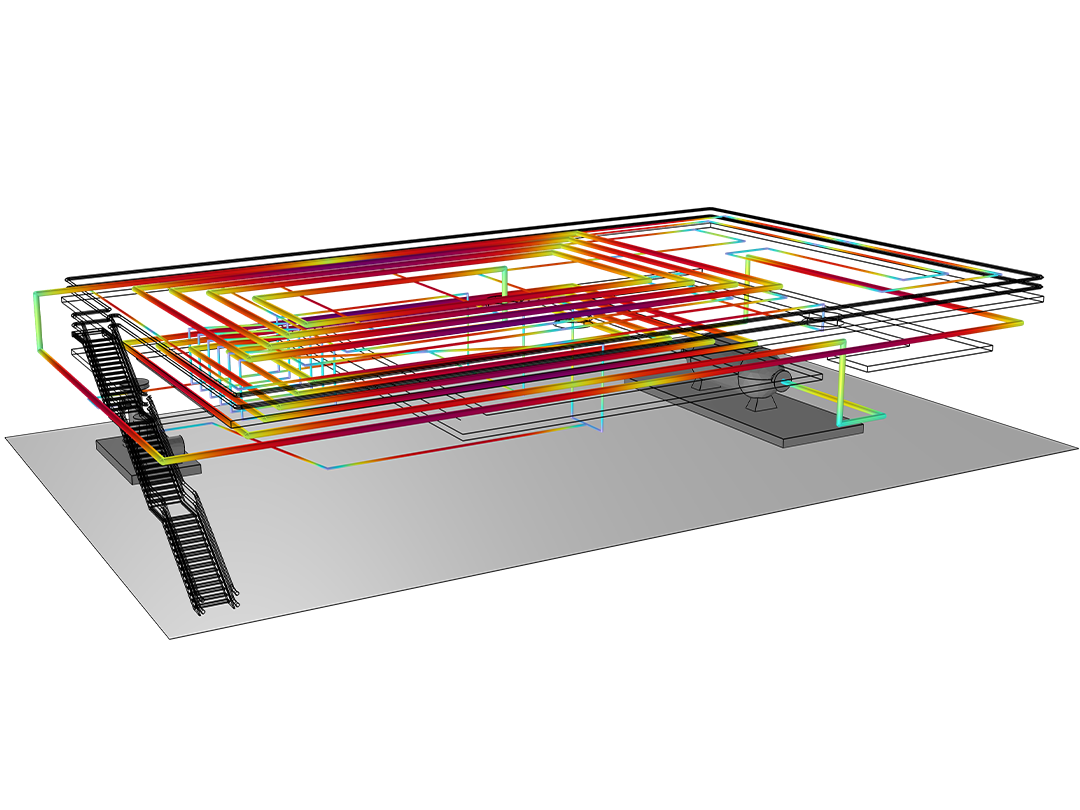

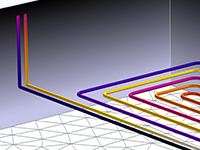

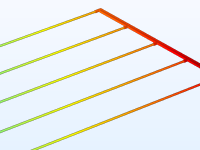

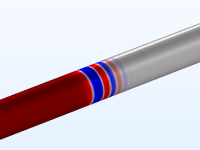

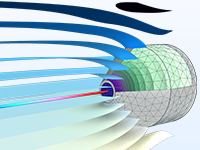

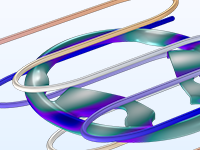

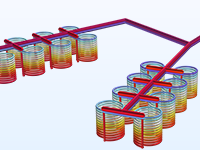

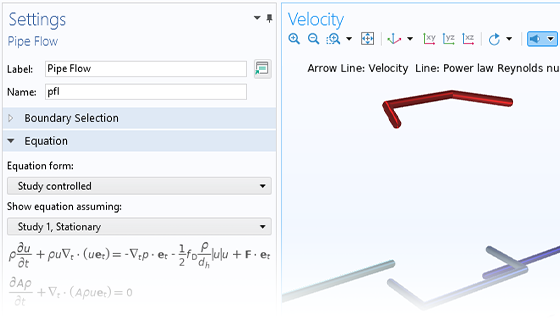

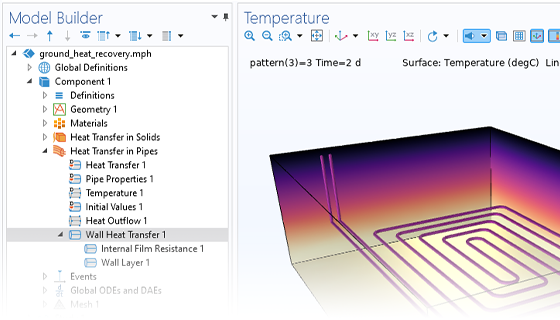

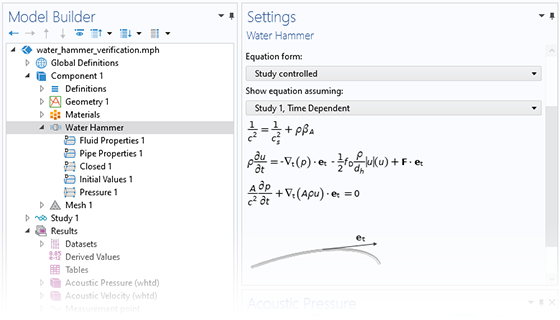

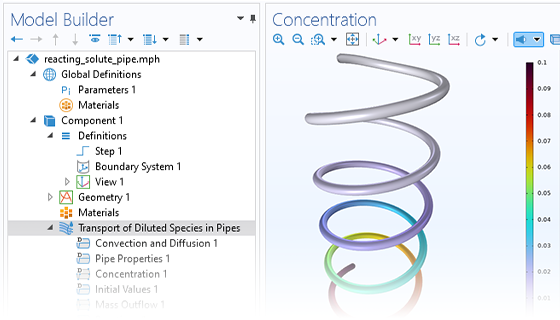

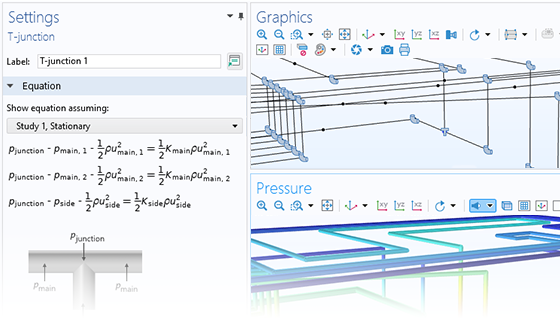

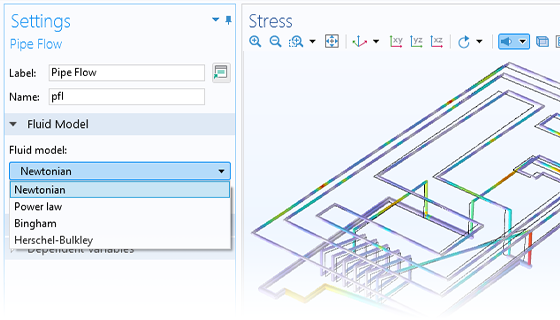

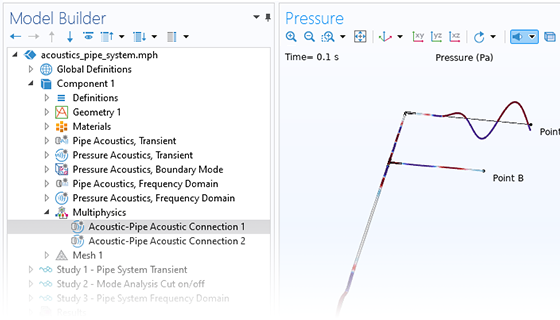

Pipes are objects with high aspect ratios, so using lines and curves rather than volume elements allows you to model piping systems without the need to resolve the complete flow field. The software solves for the cross-section averaged variables along lines and curves in your overall modeling of processes that consist of piping networks, while still allowing you to consider a full description of the process variables within these networks.

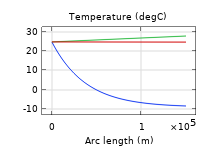

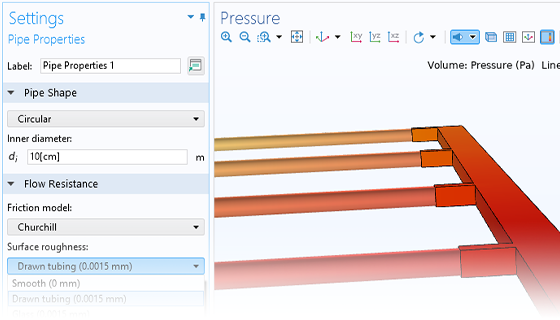

The Pipe Flow Module provides specialized functionality for defining the conservation of momentum, energy, and mass of fluid inside pipes or channels. The pressure losses along the length of a pipe are described using friction factors and relative surface roughness values. Based on this description, you can model the flow rate, pressure, temperature, and concentration in the pipes.